Cooling Towers .Labmit

Introduction

Here‘s what you‘ll learn:

- Cooling tower operating principle

- Parts and function

- Types of cooling towers: by air flow generation, by air-to-water flow, by heat transfer, and by build

- Factors affecting performance

- Mechanical maintenance practices

- Water treatment

- Applications

- And much more...

Chapter 1: What is a Cooling Tower and How Does It Work?

Cooling towers are specialized heat exchangers that remove heat from water mainly by means of latent heat loss from evaporation while coming into contact with an airstream. Aside from evaporative cooling, water is also cooled by sensible heat transfer due to the temperature difference between air and water. Cooling towers are basically heat exchangers, but instead of the usual conduction-convection of shell and tube or plate heat exchangers, it generates cooling by bringing water and air into contact.

In order to better understand the further topics, here are some basic terminologies when dealing with cooling towers.

Cooling Range

This is the difference between the water temperature at the entry and exit from the cooling tower.

Cooling Load

The rate at which heat is removed from the water.

Make-up

The quantity of fresh water which must be supplied to the water system to replace the same amount of water that evaporated.

Drift

The air droplets that become entrained or carried by the air stream coming into contact with water.

Plume

The effluent mixture of heated air and water vapors discharged from a cooling tower.

Approach

The difference between the temperature of water leaving the tower and the wet bulb temperature of the air entering.

Wet bulb temperature

The ambient air temperature at 100% relative humidity. This is measured by a psychrometer where a thin film of moisture covers the bulb of the thermometer which is then exposed to flowing air. The resulting measurement is usually cooler as compared to the measurement from an ordinary thermometer depending on the relative humidity.

Blowdown

Water that is deliberately removed from the system in order to remove parts of the accumulated solids due to the continuous water evaporation, and sludge due to impurities and bacterial growth.

Recirculation

Occurs when the discharge air re-enters the system by mixing with fresh air. This lowers the efficiency of the cooling tower.

Chapter 2: Cooling Tower Parts and Functions

Cooling tower parts may be further broken down into structural, mechanical, and electrical. Structural components are static equipment such as the basin, tower framework, fan deck, casing, and louvers. Mechanical parts, on the other hand, are the rotating equipment: fans, driveshafts, and speed reducers. Electrical parts consist of motors and their controls.

Fill

Sometimes referred to as wet deck or surface, this increases the surface area of the cooling tower to allow optimum contact surface and contact time between the air and the water, while providing minimum restriction to airflow.

Distribution System

The distribution system depends upon the type of cooling tower according to air-to-water flow. Cross-flow cooling towers use a gravity-flow distribution system where the water is distributed at an elevation above the fill. For counter-flow cooling towers, pressurized water spray systems are utilized.

Drift Eliminators

The drift eliminators prevent the escape of water droplets by creating sudden changes in the path of the air stream. As the air stream passes, large water droplets impact the walls of the drift eliminator, causing the water to fall back into the cooling tower.

Louvers

Air intake louvers are a part of the cooling tower that serves as a block for water splash-out, noise, and debris. They are a common part of cross-flow cooling towers, and are located above the cold water basin, at the bottom of the panel where the fill is packed, and are placed completely around the tower.

Casing

The function of the casing is to provide housing and to transmit loads to the tower frame. It also acts to contain water within the cooling tower.

Fan, Motor, Driveshaft, and Speed Reducer

The fans force air either in or out of the cooling tower, depending on the type of draft required for the application. The main driver is the motor. Torque from the motor is transferred by the driveshaft to the fan or to a gearbox. Large cooling towers with big and heavy fans require gearboxes to increase the torque, which eliminates the need for heavy motors, and in turn eliminates the need for a stronger structure. In some cases, belt and pulley assemblies are used instead of gear boxes.

Fan Stack

The fan stack, also referred to as the fan cylinder or fan cover, enhances the efficiency of the fan. This is done by a well-shaped air inlet to create smooth air flow into the fan. It also helps the discharge of air at higher elevations minimizing recirculation and interference.

Fan Deck

This acts as a support to the fan cylinders and as a structural member to transmit loads throughout the tower frame.

Valves

Valves are needed to control the water level inside the cooling tower. Valves used in cooling towers are isolation valves, flow-control valves, and make-up regulator valves.

- Isolation valves are used for regulating flow from a multiple-riser tower, or for isolating a cooling tower cell for stand-by or maintenance.

- Flow-control valves are used to equalize flow from different distribution basins, or water levels, on cells of a multiple-cell cooling tower.

- Make-up regulator valves are used to automatically add water to the cooling tower as some of it is lost due to evaporation, drift, and blowdown.

Collection Basin

The collection basin is located at the bottom of the cooling tower. The primary purpose of the basin is to collect falling water that has not evaporated or lost due to drift. Usually, the basin also serves as the foundation of the cooling tower. This is where chemical treatments for the circulating water are added.

Distribution Basin

This is a deep pan or small basin with holes or nozzles located above the fill. This is a part of the distribution system of a cross-flow cooling tower where gravity acts to distribute hot water evenly across the fill material.

Tower Structural Frame

The tower frame supports the whole cooling tower and transmits all loads to the foundation. Common materials used for the frame are concrete and wood. Fiberglass and stainless steel are often used.

Chapter 3: Types of Cooling Towers

Cooling towers are generally classified as follows:

Air Flow Generation. Cooling towers vary on how air flow is introduced into the system. This may be by natural, mechanical, or hybrid draft. Mechanical draft cooling towers are further divided into forced draft and induced draft.

- Natural Draft. Natural draft cooling towers utilize no mechanical drivers or fans to create air flow through the cooling tower. This cooling tower takes advantage of the difference in ambient air densities below and above the tower. Air flow is created as the denser air at the bottom of the tower travels to a lower pressure area above the tower. These towers are inexpensive but can only be installed outdoors. Also, these towers have lower reliability as they are more affected by ambient wind and temperature changes.

- Mechanical Draft. These towers use either single or multiple fans to generate air flow through the tower. Mechanical draft cooling towers are more reliable and stable than natural draft towers since air flow can be manipulated according to the cooling load required. Mechanical draft cooling towers can be further classified as forced or induced draft.

- Forced Draft. As the name suggests, this type of cooling tower uses fans or blowers to force air into the cooling tower. Air flow has high entrance velocity as it is being forced by the blower. As it passes through the tower, air flow slows down. Thus, performance is less stable compared to induced draft towers due to recirculation. Forced draft cooling towers are used in indoor applications where high static pressure is a concern.

- Induced Draft. These have their fans located at the top that draws (or induces) air from the air intake louvers at the bottom or sides of the tower. Contrary to forced draft cooling towers, this arrangement has low entrance and high exit velocity, which results in reduced recirculation. These types of cooling towers are widely used in industrial plants requiring stable performance.

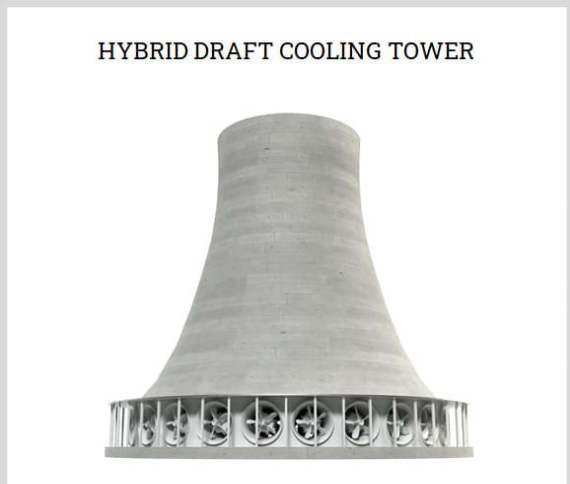

- Hybrid Draft. Its operation is the same as natural draft towers, but equipped with fans to augment air flow. Hence, they are also referred to as fan-assisted natural draft cooling towers. The fans in this setup have lower horsepower compared to forced and induced draft fans. Because of the additional draft, there is no need to construct a tall tower which may be economically impractical for a given application.

- Forced Draft. As the name suggests, this type of cooling tower uses fans or blowers to force air into the cooling tower. Air flow has high entrance velocity as it is being forced by the blower. As it passes through the tower, air flow slows down. Thus, performance is less stable compared to induced draft towers due to recirculation. Forced draft cooling towers are used in indoor applications where high static pressure is a concern.

Air-to-Water Flow. This classification divides cooling towers into cross-flow and counter-flow cooling towers. Their difference is the method of how water comes into contact with the air stream.

- Cross-flow. In cross-flow configuration, air flows horizontally through the fills across the downward fall of water. A distribution basin distributes the hot water to evenly fall into the fill by gravity through nozzles or orifices. The action of gravity eliminates the need for a pressurized-spray system. Maintenance is easier for cross-flow cooling towers since the distribution system can be sectionalized and serviced separately, eliminating downtime.

- Counter-flow. In this type, air flows parallel but opposite to the fall of water. Counter-flow cooling towers have a pressurized-spray distribution system. The need for this pressurized system puts counter-flow cooling towers at a disadvantage. Nevertheless, counter-flow types take less space than cross-flow for the same cooling load.

The table below summarizes the characteristics of each type.

| Areas of Consideration | Cross-flow | Counter-flow |

| 1. Size | • Takes more space but can be constructed lower than counter-flow | • Takes a smaller area than cross flow |

| 2.Maintenance and Operation | • Access to nozzles is available anytime • For towers using induced draft fans, access to the tower fills and drift eliminator is possible anytime | • Inspection on fills and drift eliminator can only be done during shut down. • No access to distribution system while in operation |

| 3. Water Flow Rate | • Flow can be varied by replacing the orifices installed in the nozzles while in operation | • Flow cannot be adjusted since there is no access to the nozzles |

| 4. Pumping Energy | • Pressurized water system is not required, reducing electricity cost | • Water pressure is required to ensure proper atomization of water droplets |

| 5. Water Distribution | • Potential orifice clogging • Distribution basin is prone to biological fouling | • Spray distribution improves water droplet size, which increases heat transfer |

Heat Transfer. In chapter 1, it was mentioned that there are two methods of how heat is removed from water: loss of latent heat through evaporative cooling, and cooling through sensible heat transfer. Sensible heat transfer in a cooling tower is either by conduction, convection, or a combination of both. Classification by heat transfer methods differentiates cooling towers on how these principles are applied.

- Wet or Open Circuit Cooling Towers. All cooling towers described above, from natural or mechanical draft towers to cross-flow or counter-flow, are wet cooling towers. Wet cooling towers operate mainly by the principle of evaporative cooling. Some heat is also removed through sensible heat transfer. The main advantage of wet cooling towers is their efficient cooling. In a wet cooling tower, it is possible to cool water below the ambient temperature or the dry-bulb temperature.

- Fluid or Closed Circuit Cooling Towers. In this system, the returning hot water from consumers passes through tubes or coils where sensible heat transfer happens. Outside of these tubes, water is sprayed, similar to wet cooling towers. Both latent and sensible heat is removed to the sprayed water by coming into contact with the air stream. The main advantage of this system is that water used by consumers is free from contamination.

- Dry Cooling Towers. This cooling system has the same principle of operation as automobile radiators. Hot air passes through finned tubes or coils exposed to ambient air. Heat is mainly removed by sensible heat transfer.

Build or Construction. This classification divides cooling towers according to how the structure is erected or manufactured.

- Field-erected. This cooling tower is constructed or assembled at the site where it will be used. Towers with parts having prefabricated or manufactured and shipped and assembled on-site are considered field-erected cooling towers. Field-erected cooling towers are usually found in industrial plants.

- Factory-assembled. These are also known as packaged or unitary cooling towers. Factory-assembled cooling towers are mechanically complete from the point of manufacture. These are shipped on-site with almost no required assembly process. These are used for commercial, residential, and some manufacturing plants.

Chapter 4: Factors Affecting Performance

In designing a cooling tower, there is a myriad of properties to consider, from psychrometry to heat and mass balance. Aside from studying the properties of air and water coming in and out of the system, one must also consider the resulting physical characteristics of the tower can the tower create a natural draft, or will the tower be structurally sound, and are parts susceptible for fouling and corrosion? This chapter focuses on the common parameters that affect the performance of cooling towers.

- Cooling Range and Approach From chapter 1, range is defined as the temperature difference between water entering (CW return) and leaving (CW supply) the tower, while approach is the difference between the temperature of the water leaving and the wet-bulb temperature of air entering. The cooling tower efficiency is simply expressed as,

Cooling tower efficiency = (CW return temperature - CW supply temperature) / (CW return temperature - Air wet bulb temperature) × 100%

Consequently,

Cooling tower efficiency = Range / (Range + Approach) × 100%

From these, it can be seen that a cooling tower with a smaller approach is more efficient. Cooling towers usually have a 5 to 10⁰F approach. While a small approach is desired, investment cost may be impractical since the size of the cooling tower increases exponentially as the approach is being lowered.

Usually, the range and cooling water flow rate are the parameters being balanced. This is because the heat load is already given from consumer demand, and ambient air wet-bulb temperature may not be manipulated. Increasing the range will make the cooling tower efficient. This can be done by increasing the cooling water return temperature, or by lowering the cooling water supply temperature. In either of the cases, usually, one temperature is constant due to the requirement of end users. Of these two options, increasing the cooling water return temperature is more practical since the temperature difference between air and water in contact will be much larger. The larger the temperature difference, the more heat can be dissipated.

If the only option is to lower the cooling water supply temperature, the result will also lower the approach. In turn, the design will require a much larger tower.

- Wet-bulb Temperature. This is a significant parameter for cooling towers relying on evaporative cooling. Design wet-bulb temperatures depend on existing site conditions. Thus, careful site surveys must be conducted, especially during summer months when the ambient temperature and relative humidity are high. A designer must consider publications from engineering and scientific organizations such as the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) and the National Oceanic and Atmospheric Administration for the unique, worst-case design conditions for a given location.

From the previous point, it is seen that a high ambient wet-bulb temperature will decrease the approach. Thus, at locations where there are high wet-bulb temperature conditions present, larger cooling towers are required for a given cooling load.

- Consumer Heat Load. The size and cost of a cooling tower is proportional to the heat load. Cooling towers are usually designed using the maximum consumer heat load or cooling demand. They will then be the rated capacity of the cooling tower. However, there are times when there is low demand for cooling. In these cases, the tower will operate at a lower efficiency.

In order to save energy, one method is to use fan speed control. Heat transfer rate is increased by higher air velocity. If not much heat transfer or evaporative cooling is needed, fan speeds can be reduced. This can be done by using variable speed drive motors, two-three speed fan motors, and adjustable pitch fan blades. Another option is to design a multi-cell cooling tower. In this case, one cell may be on standby during off-hours or at times of low demand.

Chapter 5: Mechanical Maintenance Practices

Cooling towers, like any other equipment, must be routinely inspected and maintained to ensure adequate and efficient delivery of required cooling while maintaining (or even extending) their expected service life. The following are some maintenance inspection practices for cooling towers.

- Inspect the cooling tower on a regular basis. Follow inspection schedules as recommended by the manufacturer or by the company policies and best practices. These may be done during plant turn-around or complete shut-down when there is minimal or no demand for cooling water.

- During the inspection, check for the following:

- Drift eliminators for overall good condition (proper position, cleanliness, etc.);

- Proper lubrication of bearings of rotating equipment;

- Proper tension of belt-and-pulley assembly;

- Operation of the level controller;

- Condition of the fill and distribution system from scale, fouling, or clogging;

- Condition of metal piping, structures, and appurtenances from corrosion;

- Any leaks on the piping and isolation valves;

Any cracks or damage on the basin, casing, fan deck, and tower frame. Address all inspection findings accordingly.

- Remove, if possible, all scales, fouling, and deposits. For the corroded metal surfaces, apply the appropriate coatings to prevent further deterioration.

- Clean the strainers and remove any debris from the basin.

- For cooling towers with side stream filters, implement regular backwashing.

Cooling Technology Institute Certification

CTI Standard 201 "sets forth a program whereby the Cooling Technology Institute will certify that all models of a line of Evaporative Heat Rejection Equipment offered for sale by a specific Manufacturer will perform thermally in accordance with the Manufacturer's published ratings" (CTI.org, 2018). A CTI certification guarantees that a cooling tower has been inspected by a CTI licensed testing agent and found to perform up to CTI standards and manufacturer specifications.

Cooling Tower Certification Tests

- Drift Emissions Test: Cooling towers emit particulate matter (PM) drift that cause corrosion, icing, transmission of legionella, and safety concerns. The Environmental Protection Agency considers cooling towers as a source of drift and requires that they meet local area permit standards.

- Particle Size Testing: The size of drift particles is a function of their distribution and water chemistry. Particles are measured in microns (µ) and can be detected with various forms of technology. The size of particles can range from 7 microns up to several thousand microns but are invisible to the naked eye.

- Sound Testing: Cooling towers can be a significant source of noise emissions. Sound testing is performed in accordance with CTI ATC-128.

- Thermal Certification: Thermal certification is based on STD-201, which requires a qualifying test and annual test. Additionally, CTI ATC-105 outlines thermal testing processes and procedures.

- Plume and Abatement Testing: Cooling towers can produce a visible plume that may be in violation of local standards. They are considered to be a safety hazard and nuisance. Clean Air evaluations are conducted under CTI standard ATC-150 to determine if plume abatement performance has been met.

Chapter 6: Water Treatment

As the water evaporates, impurities dissolve in the water and become more concentrated. Make-up water is added, which will later evaporate and leave behind more impurities. These are dissolved minerals that will later build scale to the parts of the cooling tower in-contact with water. Not only is the cooling tower affected, but also the consumers, such as heat exchangers and condensers.

Aside from scale build-up, biological fouling tends to form on surfaces. Evaporative cooling towers are particularly prone to biological fouling where an air stream carrying microbes is scrubbed by the water. Concentrated minerals present in the water due to evaporation provide a favorable environment for these microbes to grow.

Depending on the application and water parameters, methods of water treatment largely vary. There are proprietary water treatment chemicals and filtrations systems being sold on the market targeting a range of problems. The following are some common cooling water treatment methods.

- Blowdown and make-up water;

- Filtration;

- Water softening;

- Chemical treatment (corrosion inhibitors, pH control, biocides)

Chapter 7: Cooling Tower Applications

In any industrial plant, heat is generated from equipment used in different processes. The need to remove undesirable heat is a common occurrence in the industrial manufacturing processes. The same is true for commercial and residential buildings, where comfort cooling, refrigerated storage, and equipment preservation are required. If the undesirable generated heat is not removed or rejected, the machinery, equipment, and air conditioning systems will not work properly.

Because of their high efficiency, cooling towers are a widely used heat rejection system. Cooling towers vary in size depending on the application; from small chiller units for residential cooling, to 200-meter tall structures serving power generating plants. Below are some cooling tower applications.

Heating, Ventilation, and Air Conditioning (HVAC)

HVAC is used for comfort cooling of residential and commercial areas. Heat generated from people, equipment (computers, servers, etc.), lighting, solar radiation, and outdoor ambient air is absorbed by the cooling system and rejected to the cooling tower.

Refrigeration

This is for cold storage in the food and beverage industry, pharmaceuticals, air and gas generation, etc. This is similar to an HVAC system where a refrigerating unit absorbs heat from a closed space and rejects that heat to the cooling tower.

Power Generation Plants

Power generation plants use steam as the working fluid. In order to generate power, water is heated to steam by coal, natural gas, or even nuclear radiation. This heat is then converted to mechanical energy. However, some of this heat cannot be converted to energy and must be removed to complete the steam cycle. This is where cooling towers come into play.

Industrial Plant (Oil and Gas, Petrochemicals, etc.)

This is similar to a power plant. Condensers, heat exchangers, and cooling jackets all absorb heat from processes. This heat is then carried by water to be rejected through the cooling tower.

Conclusion:

- Cooling towers are specialized heat exchangers, but instead of the usual conduction - convection heat transfer of shell and tube heat exchangers, it generates cooling by bringing water and air into contact.

- This cooling is achieved through evaporative cooling and sensible heat transfer.

- There are different types of cooling towers depending on their air flow generation, air-to-water flow, heat transfer method, and construction. Each of these types has its own set of advantages and disadvantages.

- There are three important factors that determine cooling tower efficiency: relationship between range and approach, wet-bulb temperature, and cooling load.

- Because of the continuous evaporation of water, several problems arise, such as scaling and biological fouling. Common water treatment methods are water blowdown, filtration, water softening, and chemical addition.

Author

Emran Mia

Fabrication Engineer

LABMIT

Post a Comment